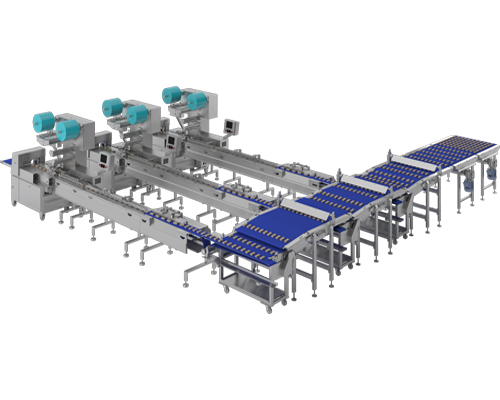

Packing line and automatic feeder for sesame halva

Application Scope:

Applicable for packing puffed, sticky and cutting foods which are produced continuously and cut completely.Besides caramel treats, it’s also suitable for egg-yolk puff, crunchy rice candy, seed candy and so on.

Main function & structure characteristics:

1.Caramel treats automatic feeding & packing line includes separating conveyor, sinking conveyor, automatic feeding unit and packing machine. The prime difference from other feeding & packing lines is that several separating devices are installed in the conveyor and feeding unit, which are especially designed for the sticky products, to make sure the products are separated completely and not sticky together before packing. This feeding & packing line can achieve the effect of continual and orderly production, low reject rate, and beautiful packing.

2.Packing speed of single line can achieve to 80-150 bags/min.

3.Power supply adpots 220V 50Hz, total power is about 16KW as the drawing (3 lines).

Advantages:

1.Equipped with automatic separation device,can separate sticky products;Automatic stopping/alignment device is also equipped, and automatic correcting device is optional.

2.The products are placed in an orderly arrangement and flowed to feeding unit, with the features of stable transmission, accurate location and high speed.

3.Dismantle the belts without tools, crumble slots are installed in the connecting places and in the bottom of the belt, easy to maintain, save time and effort.

4.Simplified structure, easy operation, convenient cleaning and maintenance,it’s easy and fast to change products with different size and setting.

5.Blue food grade anti-sticky belt is adopted in the conveyor, and optional white belt is available.

6.High quality electric components are adopted in control system; intelligent PLC, touch screen and wonderful HMI, make the operation easy and intuitive.

00989131104081

00989131104081

Add: No.25 , The first sub, 3rd St, Jey Industrial Zone, Isfahan,Iran

Add: No.25 , The first sub, 3rd St, Jey Industrial Zone, Isfahan,Iran Tel:

Tel: